ProPoint Plus Aspirating Smoke Detectors

- 1 – 4 Individual detectors per aspirator (providing up to 4 separately identifiable areas)

- High performance optical ‘Scatter Chamber Detectors’ (SCD)

(or)

- High performance optical ‘Scatter Chamber Detectors’ (SCD) and enhanced CO detection

- Multiple language, multi-function LCD display

- Simple install and commission process generally without the need for a laptop connection

- Simple Class A, Class B, Class C and Prison sensitivity configuration set up

- Inbuilt algorithm to reduce unwanted alarms

- Airflow monitoring per pipe

- Approved to EN54-20 & AS7240-20

ProPoint Plus aspirating smoke detectors utilise ‘Optical & CO’ or ‘Optical’ only Scatter Chamber Detectors (SCD’s) and can provide up to four separate detectors in each aspirating unit

Each SCD can be individually configured to Class A – high sensitivity, Class B – enhanced sensitivity and Class C – normal sensitivity

Product Details

ProPoint Plus Optical ‘Smoke’ and ‘Smoke/CO’ detection

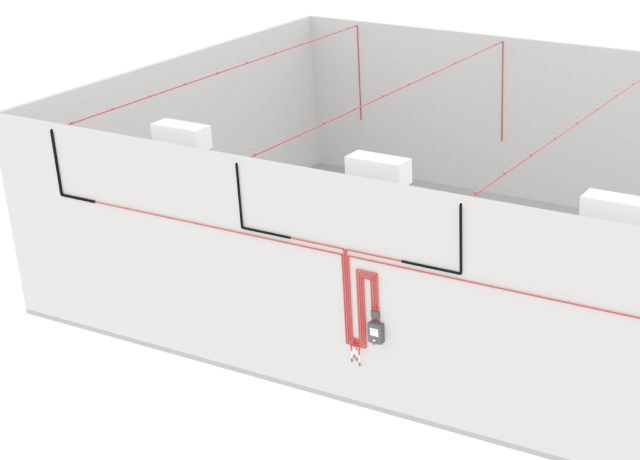

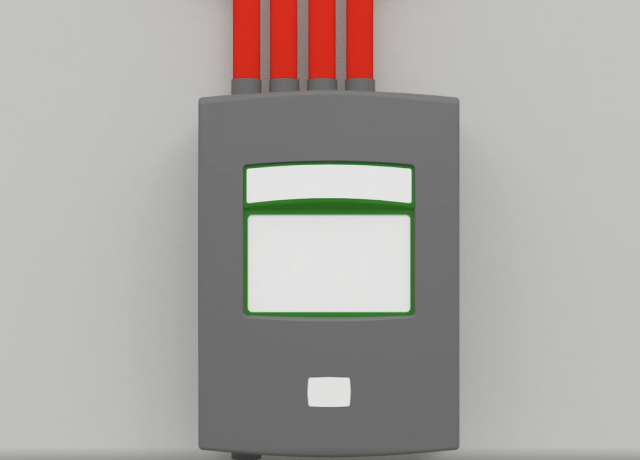

Aspirating detection is now a recognised solution for many different fire detection applications. ProPoint Plus provides up to four separate detectors within a common aspirator enclosure and therefore provides four individually identifiable areas of detection per aspirator.

Each of the four plug-in ‘Scatter Chamber Detectors’ (SCD)’s detector modules can be either ‘optical’ only or combined ‘optical/enhanced CO’ detectors, the CO sensor is only suitable for small room applications. Independent and integrated alarm decision making through the use of complex algorithms extend the range of particle detection, confirm genuine alarms and reduce unwanted alarms.

Installation, configuration and commissioning of ProPoint PLUS detectors is very simple and installer friendly.

Configuration to either Class A, Class B or Class C sensitivity options is achieved through a multi-language, multi-function LCD display without the need for a laptop connection.

Detector set up allows the installer to configure the detector sensitivity to an equivalent setting, as a known number of point type smoke detectors for each Class A, Class B and Class C system. This ensures the system specifier, designer, installer and commissioning engineer configure the ProPointPlus SCD’s to the correct sensitivity for the particular application.

Aspirator fan speed and airflow configuration is a also a very simple process allowing ProPoint Plus aspirating detectors to be installed in a variety of applications with short and relatively long pipe runs.

| ProPoint PLUS OPCO | ProPoint PLUS OP4S | |

| Supply Voltage | 21 – 28VDC | |

| Current Consumption @ 24VDC, 100% Fan 4 pipe | 580mA quiescent | 620mA alarm | |

| Temperature Range Tested to EN54-20 | -10˚C to 55˚C (32˚F to 131˚F) | |

| Application Sampled Air Temperature | -20˚C to 60˚C (-4˚F to 140˚F) | |

| Humidity | 10 – 93%RH (no icing / non-condensing) | |

| IP Rating | IP30 | |

| Cable Access | 10 x 20mm knock outs | |

| Cable Termination | Screw terminal blocks (0.2 – 2.5mm2, 30 – 12AWG) | |

| Pipe Outer Diameter | 25mm, push to fit tapered inlet | |

| Alarm Indications | Pre-alarm, Fire | Pre-alarm, Fire 1, Fire 2, Fire 3 |

| Other Indications | Supply Healthy, General Fault, OLED Display with four navigation buttons | |

| Fault Contact | Rated at 30VDC 1A maximum [Normally closed] | |

| Programmable Output Contacts | 5 contacts rated 30VDC 1A [Volt-free change over contacts with 28 programming options] | |

| Programmable Inputs | 3 monitored inputs that may be configured for Isolate, Reset, Silence, Battery Fault and Mains Fault | |

| Event Log / Data Retention | 24,000 events stored on FIFO basis (alarms, actions, faults and data points) (Approx 30 day historical graph data) | |

| Sensitivity Range | Optical Detection Range: 0.12%obs/m to 11%obs/m Carbon Monoxide Detection Range: 1 to 150 ppm | Optical Detection Range: 0.02%obs/m to 6.0%obs/m Hole Sensitivity Range: 0.5%obs/m to 6.0%obs/m |

| Threshold Settings Recommended Maximum | Class A – 3 holes per pipe @ A1 to A3 Class B – 5 holes per pipe @ B1 to B5 Class C – 8 holes per pipe @ C1 to C8 Class C Escalator Mode – 8 holes per pipe @ ESC1 to ESC8 Class C Prison Mode – PR2 using Sample Head (61-988-00) | Class A – 15 holes per pipe @ Alarm Level 1%obs/m Class B – 15 holes per pipe @ Alarm Level 2%obs/m Class C – 15 holes per pipe @ Alarm Level 4%obs/m |

| Threshold Settings Compliant Maximum EN 54-20 | Class A – 15 holes per pipe @ Alarm Level 1.1%obs/m Class B – 15 holes per pipe @ Alarm Level 3.2%obs/m Class C – 15 holes per pipe @ Alarm Level 11.5%obs/m | |

| Sampling Pipe Network | Number of inlet ports: Up to four Pipe Network Design Tool: ProFlow Maximum pipe length: Specific to individual design. To be compliant to local design codes, and verified by ProFlow. | |

| Airflow Monitoring | ‘High Airflow’ and ‘Low Airflow’ fault monitoring | |

| Standards / Approvals | EN 54-17, EN 54-20 AS 7240-20 UKCA CE | |

| Weight | 3kg (6.6lbs) | |

| Dimensions (mm) | 380(H) x 250(W) x 137(D) | |

- ProPoint PLUS EN54 Tech Sheet

- Product Feature Focus – ProPoint PLUS OPCO – Escalator Mode

- Product Feature Focus – ProPoint PLUS OPCO – Prison Mode

- Generic Design & Installation Guide

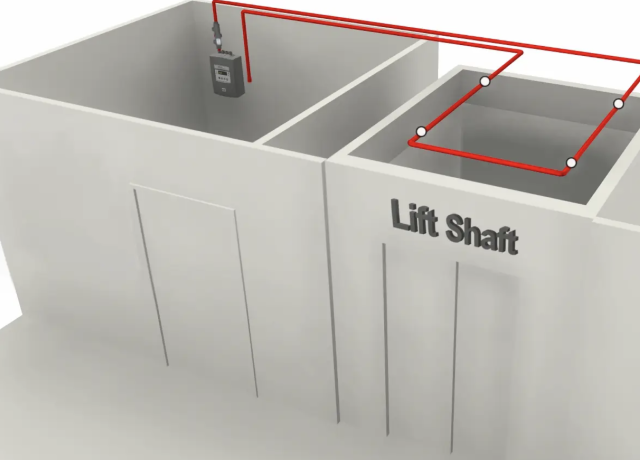

- Lift Shaft Design Guide

- Atria Design Guide

- Warehouse Design Guide

- Cold Store Design Guide

Technical documents such as Manuals, Software downloads, BIM families, and more are available via our Client / Support Portal. To access, please Sign up or Login to your account.

Sign up or login to your accountRelated Products

- Cirrus HYBRID Aspirating Fire & Smoke DetectorsView Product

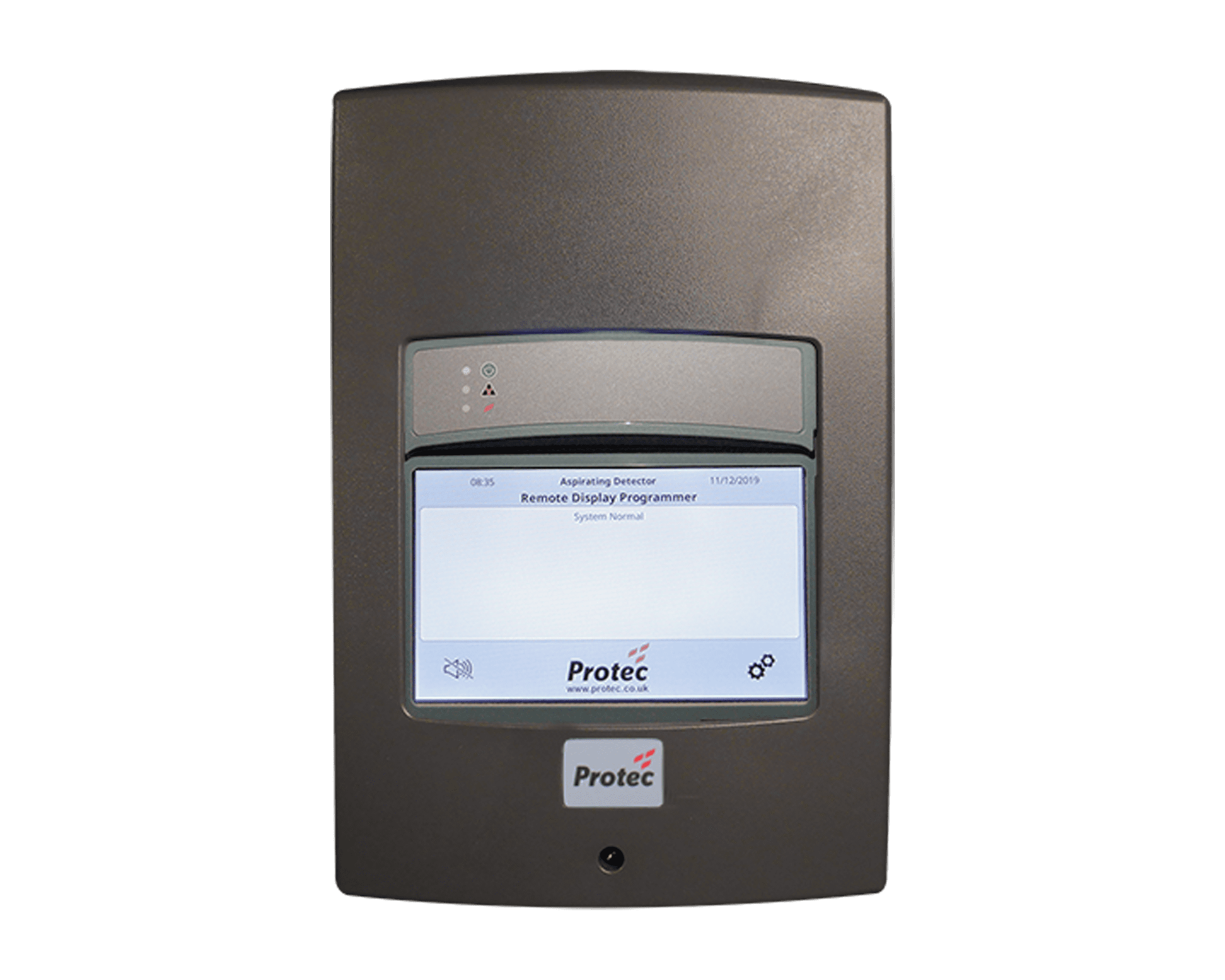

- Aspirating Detector Remote Display ProgrammerView Product

- Sampling Pipe & AccessoriesView Product

- 6500 Fire Alarm Control PanelView Product

- 6100 Single Loop Fire Alarm PanelView Product